When it comes to how consumers want to take their medicine, softgel are the dosage delivery of choice because they are convenient, easier to digest, and have better absorption.

A softgel is an oral dosage form consisting of a gelatin and non-gelatin based shell surrounding a liquid fill. They are produced through a process known as encapsulation, using the rotary die encapsulation process invented by Robert Pauli Scherer.

How does it work? Two flat ribbons of shell material are manufactured on the machine and brought together on a twin set of rotating dies. The dies contain recesses in the desired size and shape, which cut out the ribbons into a two-dimensional shape and forms a seal around the outside. At the same time, a pump delivers a precise dose of fill material through a nozzle incorporated into a filling wedge.

After that, the wedge is heated to facilitate the sealing process. The wedge injection causes the two flat ribbons to expand into the die pockets, giving rise to the three-dimensional finished product. After encapsulation, the softgel are dried for up to two weeks depending on our clients’ needs.

Liquid encapsulation technology allows our customers to address unique formulation and delivery challenges. Hygroscopic materials, herbal pastes, and other complex products can be encapsulated using our vegetarian liquid capsules, which is gaining popularity in nutraceuticals as consumers continue to seek out cleaner labels.

Work with Us

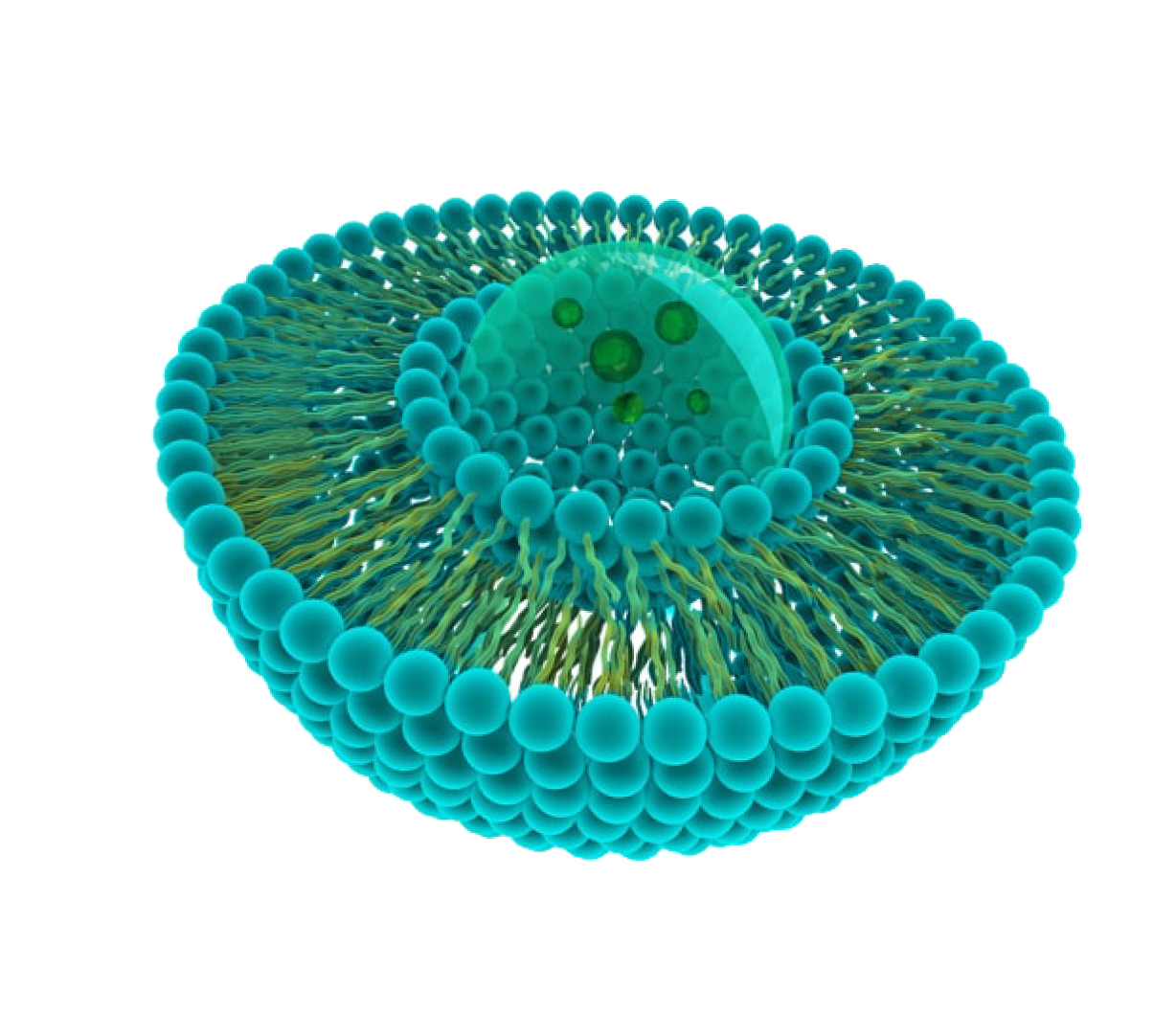

Aspire recognizes that bioavailability is a key challenge in the ever growing complex nutraceutical and pharmaceutical space. By leveraging liposomes as vehicles for better bioavailability, we can formulate low-dose actives that offer the same health benefits for consumers.

Since its discovery by Dr. Alec D. Bangham in the 1960’S, there has been a lot of research conducted on liposomes to demonstrate their efficiency and efficacy as a drug delivery system. However, there are only handful of commercial products in the pharmaceutical and supplement space due to the developmental and production challenges.

Liposomes are versatile delivery systems that theoretically can be used for any bioactive compounds. A liposome is composed of one or more phospholipid bilayers, which closely resembles the structure of cell membranes. Its structure provides multiple absorption routes, which greatly enhances the bioavailability of the encapsulated compounds.

The naturally-derived phospholipid forms spherical-shaped nano vesicles encapsulating hydrophobic compounds in its outer shell and hydrophilic ingredients in the inner core.

With carefully designed and modulated liposomal compositions, we can further improve the absorption of its payloads by enhancing their solubility and permeability. Liposomes are non-toxic and biologically degradable.